Zephyr ESR C

Advanced Image Analysis for Dry Particle Applications : particle size, shape, and color characterization.

Vibration-based primary dispersion coupled with a conveyor belt transport system for precise and stable particle analysis.

30 µm to 50 mm

Particle size range for dry sample

analysis on the conveyor belt, with

a resolution of 10 µm/pixel.

Integrated Dispersion

Conveyor Belt

For dry samples, a vibrating chute disperses

particles directly onto the conveyor belt.

Real-Time Particle

Analysis with AI

Equipped with advanced artificial intelligence

for precise and automated characterization.

This technology is based on an innovative vibration dispersion system and a conveyor belt transport mechanism, specifically designed for efficient handling of dry samples.

The system ensures that particles remain stationary on a flat surface during analysis, enabling high-precision sieve diameter estimation and strong correlation with traditional sieve analysis methods.

This unique feature enhances measurement accuracy and reliability.

The Zephyr ESR C is equipped with a patented transport system and a high-resolution camera, ensuring exceptional accuracy in granulometric measurement.

By maintaining particles in a stable position during analysis, the system minimizes movement-induced errors, resulting in highly precise and repeatable measurements.

The high-resolution camera, with a detection capability of 10 µm/pixel, captures detailed images of each particle, allowing for an accurate assessment of size, shape, and distribution.

This precision guarantees a strong correlation with traditional sieve analysis, making the system ideal for quality control and research applications.

Equipped with advanced AI, the Zephyr ESR C offers detailed and comprehensive characterization of pharmaceutical powders, granules, and other materials.

It enables granulometric analysis, intelligent particle sorting, and recognition of different particle populations.

Fast and highly correlated with sieve granulometry, the Zephyr ESR C provides deeper insights into sample properties, including shape parameters that reveal physical characteristics such as abrasiveness, flowability, and compactness.

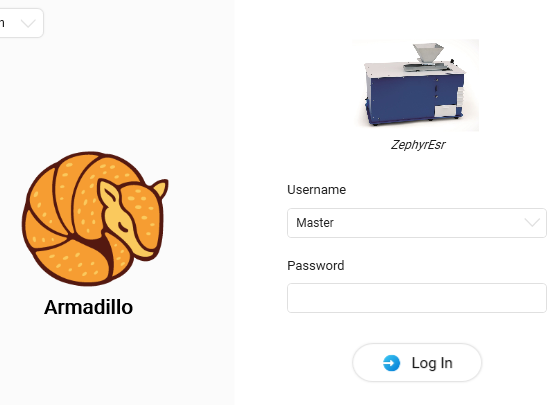

The instrument is operated via the Armadillo software, which controls the entire analysis process, including methods, statistics, reporting, and data storage in a proprietary Occhio database.

Our software enables a comprehensive analysis, providing a detailed assessment of particle size, shape, and distribution for deeper sample understanding.

Occhio Zephyr ESR C can measure :

- Particle Size

- Particle Shape

- Particle Transparency

- Particle Color

- Sieve Granulometry Correlation

| Particle size range | 30µm to 50mm with 10 sµm/pixel resolution |

| Dispersion System | Integrated vibrating chute and conveyor belt |

| Artificial Intelligence | The Armadillo software's AI can recognizes and classifies different particle populations. |

| Automatic Cleaning | Integrated intense vibration and fine brushes ensure minimal maintenance. |

Are our products right for you ?

Ensure that your operation is running as smooth and efficient as possible. Get in contact with an Occhio representative who can help you choose the correct instrument and software combination, optimized for your application!

Contact Us !