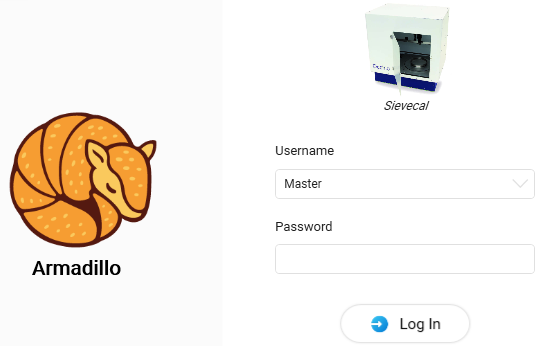

Sievecal

Precision Sieve Verification and Calibration.

Image analysis technology for standard sieve quality control, ensuring compliance with ASTM and ISO norms.

38 µm to 12 mm

Measurement range for sieve openings.

Motorized Scanning Table

Allows fast and accurate scanning of the

entire sieve surface.

Fully Automated Calibration

Automatically measures sieve openings and wire diameters, ensuring precise calibration..

The Sievecal is an advanced instrument designed for the verification and calibration of standard sieves, ensuring full compliance with ASTM and ISO standards.

Using advanced image analysis technology, this fully automated system accurately measures sieve openings and wire diameters, providing fast, reliable, and reproducible quality control.

Sieve calibration is a critical process in industries such as particle size analysis laboratories, pharmaceuticals, food processing, chemicals, and minerals.

A sieve that does not meet specifications can lead to incorrect analysis results and production errors.

The Sievecal replaces traditional manual inspection methods (often time-consuming and error-prone) with a fully automated, standardized process, ensuring maximum precision and efficiency.

Data and images of each individual particle are stored in an Occhio binary database.

The Occhio database is a proprietary binary storage system that records detailed particle analysis data, including high-resolution images, size, shape, transparency, and concentration.

Integrated with Armadillo software, it allows advanced visualization, statistical analysis, and comprehensive reporting.

Occhio Sievecal can measure :

- Sieve Opening Size

- Sive Wire Diameter

| Sieve Opening Range | 38 µm to 12 mm |

| Compatible Sieve Diameters | 8 inches and 12 inches (ASTM & ISO standards) |

| High-resolution image analysis | With optimized lighting |

Are our products right for you ?

Ensure that your operation is running as smooth and efficient as possible. Get in contact with an Occhio representative who can help you choose the correct instrument and software combination, optimized for your application!

Contact Us !