Zephyr LDA

Image analysis technology for dry applications: particles size, shape and colour characterisation.

Vibrating primary dispersion coupled with secondary air stream dispersion.

7 µm to 5 mm

Particle size range for dry analysis.

Optional HR Upgrade

For the measurement of particles in

the size range from 1 µm to 5 mm.

Ultra-high-speed shutter camera

For more accurate particle dimensioning and a better understanding of your sample.

The Zephyr LDA operates on a principle similar to that of laser diffraction instruments, but with a key difference:

It replaces laser sensors with an ultra-high-speed shutter camera.

Image analysis is a direct measurement method, providing more accurate particle dimensioning and a better understanding of your sample.

For example, laser methods are limited when it comes to measuring fibers, as they only provide an equivalent sphere size.

With image analysis, the Zephyr LDA can qualify fibers by measuring length, thickness, and size distribution, information that laser methods cannot provide.

This makes Zephyr LDA far superior in capturing the true size distribution of fiber samples, ensuring a more accurate result.

The Zephyr LDA is simple to use, fast, and reliable, making it an ideal solution for process and quality control measurements. Additionally, it integrates seamlessly with sieve size and laser methods, enabling easy switching between methods without compromising accuracy.

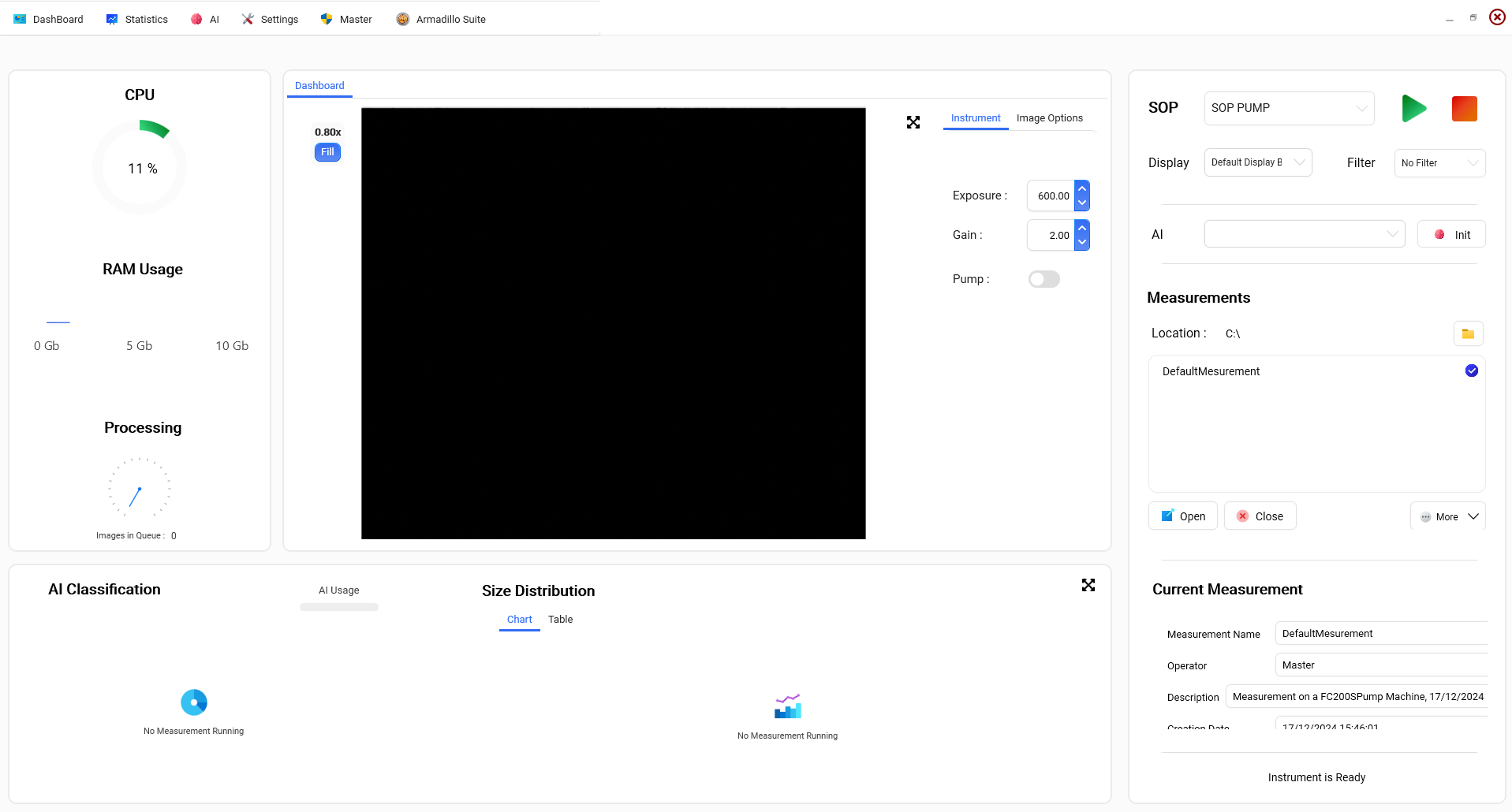

Data and images of each individual particle are stored in the Occhio binary database. The Zephyr LDA is powered by Armadillo software, which manages the entire analysis process, including Standard Operating Procedures (SOP), statistics, reporting, and data storage.

It provides a powerful, user-friendly solution for precise particle analysis in dry applications, offering a comprehensive range of features and excellent accuracy for a wide variety of materials

Occhio Zephyr LDA can measure :

- Particle Size

- Particle Shape

- Particle Transparency

- Particle Color

- Dry Particles

| Particle size range | 7µm to 5mm |

| Dispersion method | Vibrating primary dispersion coupled with secondary air stream dispersion. |

| Optional HR Particle Size Range | 1µm and 5mm |

Are our products right for you ?

Ensure that your operation is running as smooth and efficient as possible. Get in contact with an Occhio representative who can help you choose the correct instrument and software combination, optimized for your application!

Contact Us !