Ipac 2

Image analysis technology for wet applications: particles size, shape, transparency and concentration .

The Ipac 2 is capable of adapting to the analysis of suspensions and or emulsions containing particles ranging from 0.2µm to 1mm in size.

0.2 µm to 1 mm

Particle size range for

wet analysis.

Ultra precision

syringe

For generate more accurate sample flow control.

Adaptable syringue size

If your application requires larger sample

Auto Dispensing Robot Option

Save time and increase measurement efficiency.

The Ipac 2 was originally developed for protein aggregation research and vaccine quality control, but it is now widely used across various industrial and research applications.

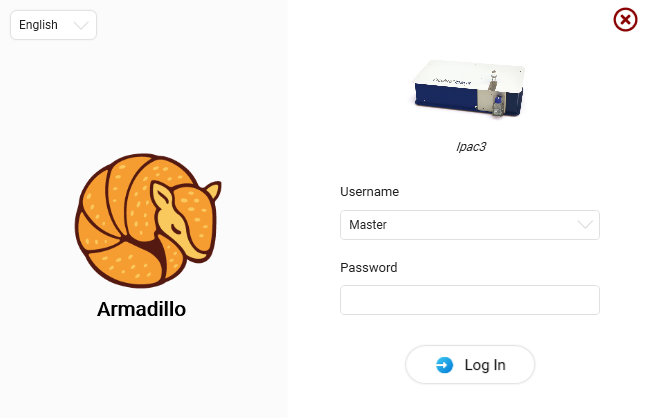

Its compact and reliable design minimizes manual intervention, with most adjustments made through the intuitive Armadillo software, included with all Occhio instruments.

The microchip, where samples are measured, can be easily replaced using a simple latch system, allowing for quick changes.

The efficiency and reliability of the Ipac 2 make it a preferred choice in fields such as protein aggregation, vaccine quality control, antibiotic efficacy testing, CMP (Chemical Mechanical Planarization) compound analysis, fuel contamination QC (below 5 µm), and liquid soap R&D.

The sample dispersion system uses a precision syringe and integrated motor for accurate measurements.

The minimum sample size required is just 20 µl, but the syringe can be adjusted to accommodate larger sample volumes as needed.

The ADR option designed for the Ipac 2, automating the entire analysis process.

The robot works in coordination with the instrument to mix, disperse, and measure the sample without human intervention.

It can test up to 96 samples continuously, optimizing time and freeing up resources for other tasks.

Data and images of each individual particle are stored in an Occhio binary database.

The Armadillo software controls the entire analysis process,ensuring complete

and precise management of results.

Occhio IPAC 2 can measure :

- Particle Size

- Particle Shape

- Particle Concentration (particle counting)

- Particle transparency

| Particle size range | 0.2µm to 1000µm |

| Sample Volume Min | From 0.02ml |

| Sample Flowing | Precision syringe |

| Cell Thickness | Variables thickness |

Are our products right for you ?

Ensure that your operation is running as smooth and efficient as possible. Get in contact with an Occhio representative who can help you choose the correct instrument and software combination, optimized for your application!

Contact Us !