Quality control of atomized powders

Atomization is a major process in the production of powders both in metallurgy and ceramics.

It is important to reduce the number of irregular particles so as to maintain the ability of the atomized powders to properly fill in a mold or to circulate in an air flow.

A common problem is the presence of satellites, nodules on the particle.

To ensure the production of spherical and well calibrated particles, a very sensitive and highly accurate quality control process must be implemented.

Thanks to a specific shape descriptor exclusive to Occhio technology, satellite detection is fast, simple, and accurate.

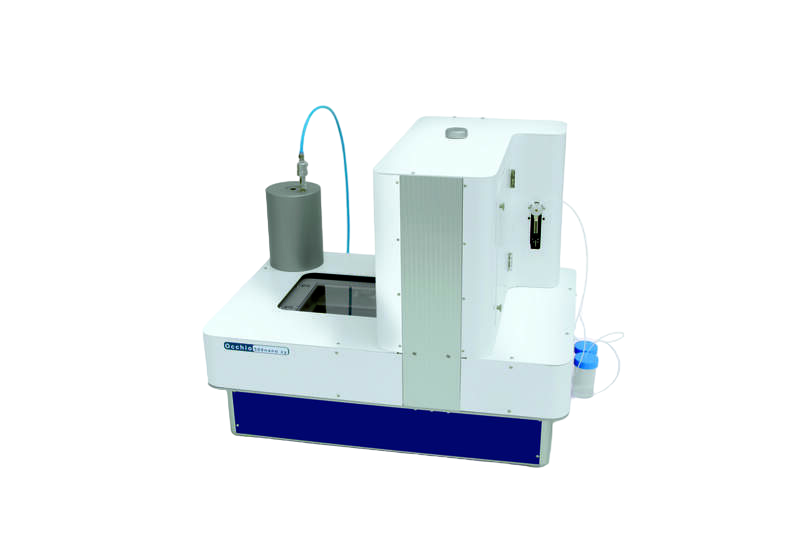

The Occhio 500 Nano XY proves to be a unique instrument to disperse and image such powders. Combined with the exclusive shape analysis capabilities of the software, it becomes a very sensitive tool for identifying deviations in the atomization process.

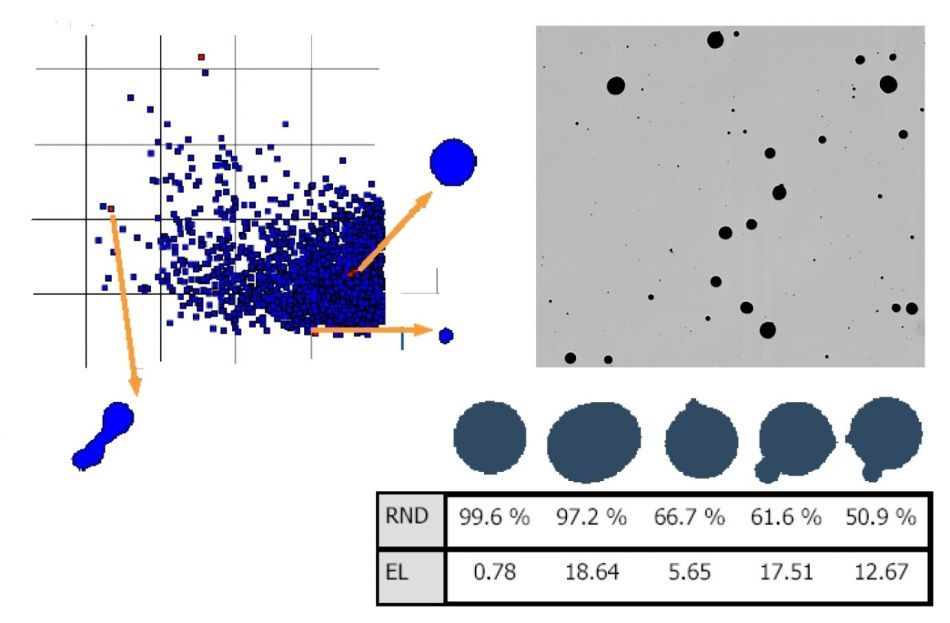

A scatterplot of elongation versus sieving diameters gives a very comprehensive insight into the production.

From such data, the number of particles exceeding a critical elongation factor or a given size is precisely monitored.

Each output can be compared to a reference sample.

The subtle morphometric measurements computed by Armadillo (roundness (rnd) and elongation (el)) provide unrivalled precision for accurate detection and categorization of satellite particles.

500 Nano XY

Are our products right for you ?

Ensure that your operation is running as smooth and efficient as possible. Get in contact with an Occhio representative who can help you choose the correct instrument and software combination, optimized for your application!

Contact Us !