Characterisation of CMP slurry, high concentration suspention

CMP (chemical-mechanical planarization) process uses colloid slurry to polish semiconductor wafers surfaces. The presence of impurities or over-sized particles must be quantified constantly during slurry production. Ipac 2 CMP offers a complete method to improve particles counting for slurry suspensions.

The IPAC 2 platform is based on high-end imaging devices and the newest generation microchip cell.

Where we put our efforts :

- Increasing the detection of the finest particles by using a dedicated optical bench with a resolution of 172nm/pixel.

- Reduce sample dilution, by using 50µ cell thickness we can reduce, or even eliminate, sample dilution (typically 1:1; 1:10; 1:100). The lowest sample dilution improves measurement reliability and sample stability.

- High stability lighting and imaging device, we eliminated the derive of the acquisition device (compared with standards light obscuration devices)

- Dynamic background function, this intelligent software compares each image with the previous one and allows recognition of only moving particles. This means that dirt on the cell will be filtered out and not counted as a particles giving us the most accurate counting results.

| Calibration | 172 nm/pixel |

| Camera Sensor Size | 12 MP |

| Cell Thickness | 50 µm |

| Sample dilution | 1:1 (undiluted) |

| Sample type | Colloidal silica slurry |

| Pump type | Precision syringe |

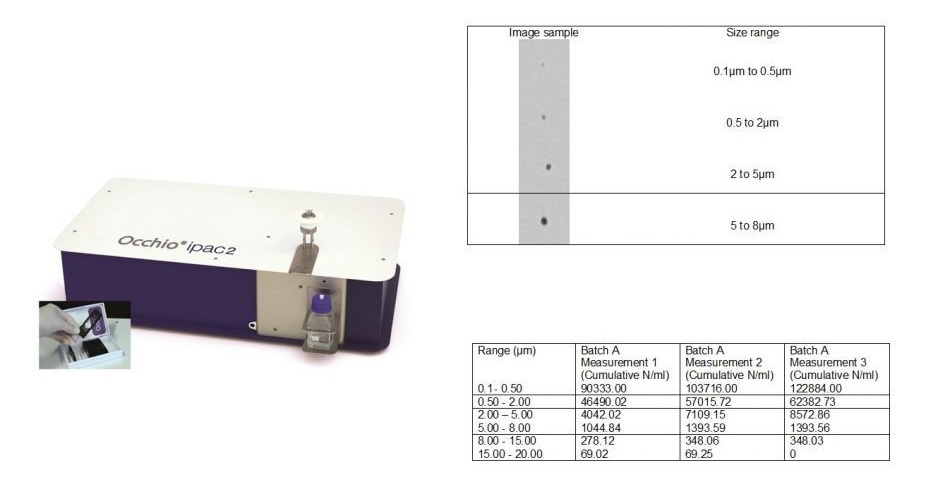

During the measurement the camera acquires and processes the images in real time, up to 18 images processed per second. All the particles, visible on the image, are identified and stored in the corresponding size classes. Counting distribution is refreshed continuously until the end of the analysis. The adjacent table shows four particles in different size ranges.

Ipac 2

Are our products right for you ?

Ensure that your operation is running as smooth and efficient as possible. Get in contact with an Occhio representative who can help you choose the correct instrument and software combination, optimized for your application!

Contact Us !